SCR-284-A

Part 1

Bench

and Ops Notes. Repairs, Test/break out boards, Modifications and power.

This series in 5 parts.

INDEX Click to Navigate

Intro

Receiver Power - Bench power for the receiver.

Replacing

Capacitors - Do your self a favor and change all those postage stamps.

80

Meter Receiver Conversion - Lower 80 meter CW conversion.

BFO

Increased Injection - Better CW and SSBSC reception.

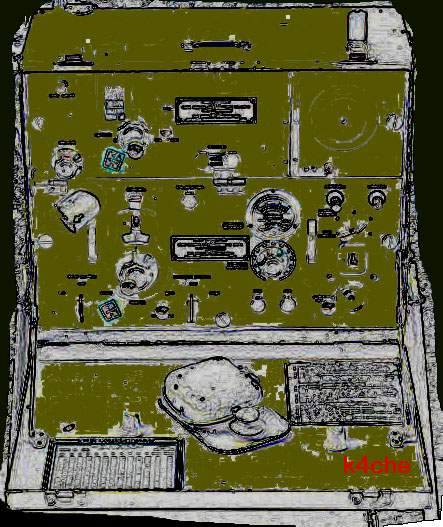

KB3ELD

- Dave's Fort Mott operating display.

The BC-654 is a great set - Easy to recognize with the

classic fold down desk.

Dave

KB3ELD is our MRCA expert on the SCR-284.

Most

of the schematics and drawings in TM-11-275 are arranged IAW serial numbers

of the sets.

When working

on the BC-654 if in doubt RTFM.

Reprints of TM 11-275 can be ordered at wa5cab.com. They are excellent reprints..

Do your self a favor and take your schematics and wiring diagrams to your local "Copy Place" and make large copies. Easy on the eyes.

Receiver

Power Up

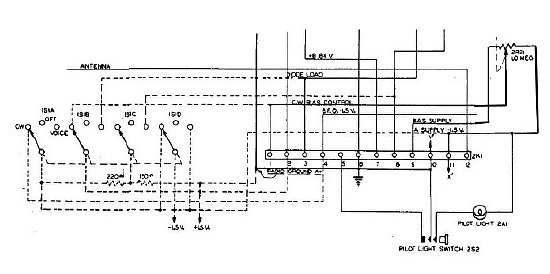

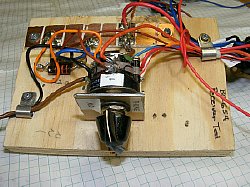

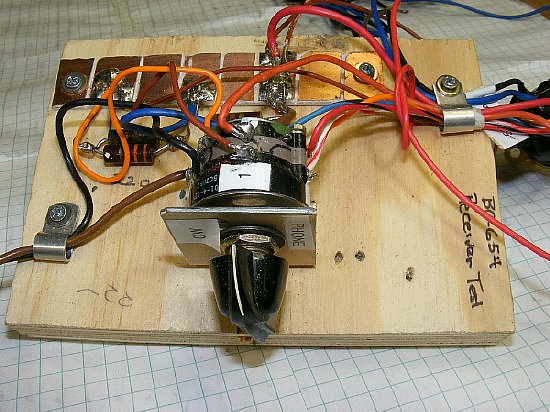

Receiver CW/ PHONE mode and power board.

I wanted to post this WARNING note but could not decide where to place it. Anyway here it is:

WARNING: Testing tubes: Do not test filament (continuity) with a analog VOM unless you are sure of the voltages applied during a resistance test. Normally you will use the low ranges of X1 and X10. My Simson 260 was OK on the lower ranges and used a 1.5 volt battery. On the higher ranges the meter used a 9 volt battery.

Dashed line

circuit above left represents the "Transmitter" control wiring

to control power and select CW/VOICE mode. Its easier to set up the receiver

on the bench by duplicating this dashed line circuit and build it up on

a small board and attach to the main receiver terminal strip. A 4 pole

double pole rotary switch might be hard to find so just substitute a couple

of 2 pole double throw switches - or just use a alligator clip and nails

for contacts.

Don't omit the 150 and 220 ohm resistors.

Receiver Power up: 1.5V

- Minus to the dashed line circuit which feeds Terminal 11.

1.5

+ Pos to radio ground Terminal 10

B + to Terminal 7 of the receiver terminal

strip 2K1.

B - minus Terminal 10

Bias - minus Terminal 9 (Use a 9 volt

battery for testing with 1 K resistor.)

Bias + plus Terminal 10

Replace

all "Postage Stamp" and tubular paper capacitors.

Do

your self a favor before working on the BC-654 receiver or transmitter.

Replace all the molded "Postage Stamp" capacitors and tubular

paper capacitors - Do them all - don't get

creative and decide which caps are critical - just dig in and replace

them. In the long run you will save time in achieving your goal of having

a working and reliable set. The purist restorer is probably not going

to be happy with this process but my mission is to have a working reliable

set for display at the next rally without spending a lifetime repairing

the set.

Its easy to spot the Postage Stamps as they are ugly. Also plan on replacing the large electrolytics. I found that 3 out of 10 Postage Stamps were obviously bad. All of the electrolytics in the receiver had gone South.

CLICK

to enlarge

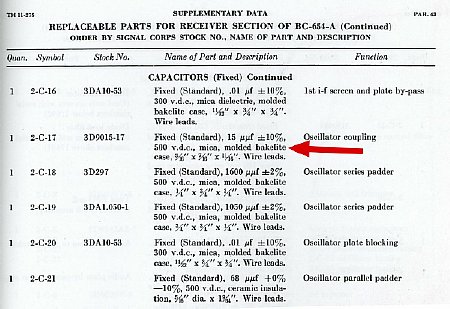

The

Parts List in the Supplementary Data section in TM 11-275 is excellent

and includes a "Function" column. You want to replace the "mica

molded bakelite case" capacitors.

Q. A lot of the capacitors listed in the receiver "Replaceable Parts" list are listed as 500 v.d.c but the actual "Tube Socket" voltages in the receiver are less than 100 volts. Do I need the 500 v.d.c. caps?

A. NO. You can examine each circuit in the receiver and often use caps that have a voltage rating less than listed but as a general rule I would go with a 200 volt rating or higher in the receiver and use the specified voltage ratings in the transmitter.

Q. How about voltage ratings for capacitors on the transmitter?

A.

You can examine each circuit but as a general rule I would go with the

voltages listed.

CLICK

to enlarge

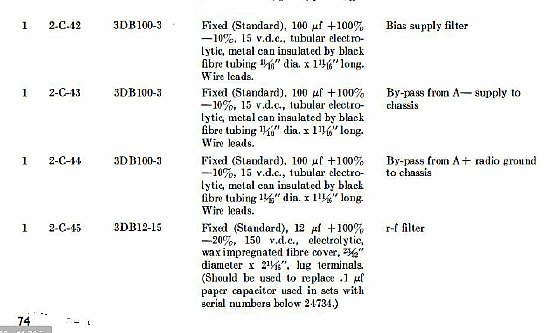

Receiver Tubular Electrolytics

Also

check the "Tubular Electrolytics". On one receiver I found that

they were all bad.

There are only 4 Tubular Electrolytics in the Receiver

- Bad C-43 and C-45 Electrolytics can cause some interesting noises in

the receiver. Just change them and get with the project.

The same procedure is followed for the transmitter.

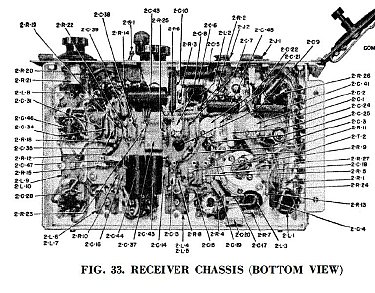

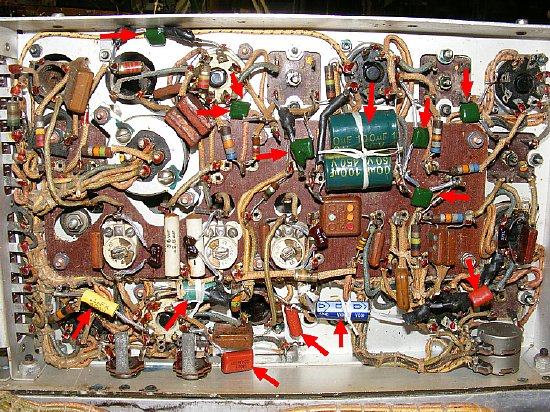

The

Receiver and Transmitter Chassis photos assist in locating parts but for

better detail of component boards etc. don't forget to check the "Connection

Diagrams" in the rear of the manual.

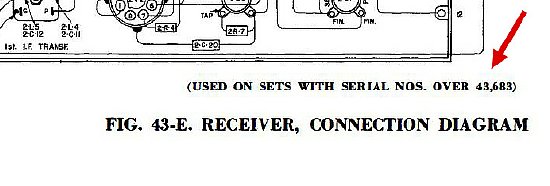

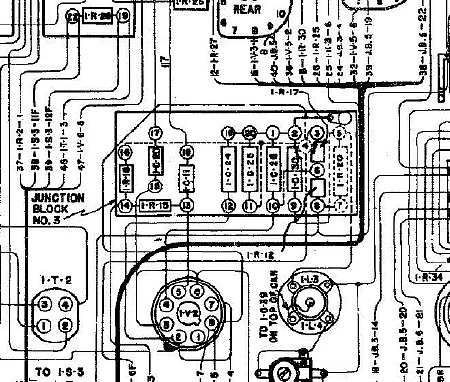

Connection

Diagram

The "Connection Diagrams" for the transmitter and receiver in the rear of the manual are a great aid in locating capacitors. Figures 43x and 45x depending on the serial number of your set.

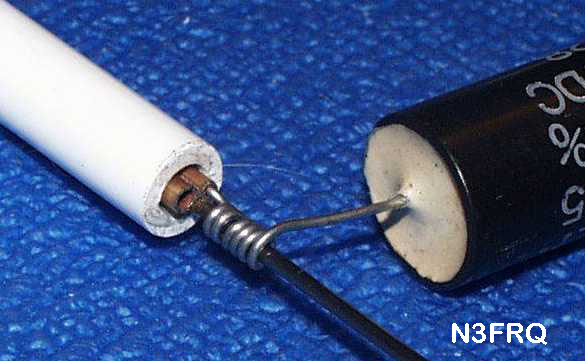

N3FRQ

photo( link below) - A tool for forming "pigtails"

on the replacement capacitors.

I prefer to just clip the leads on the old caps as close to the body as possible leaving the leads intact and then take the new replacement capacitor and form "Pigtails" on the leads and simply place the new "Pigtail" on the older leads - crimp slightly - and then solder. A very fast replacement process. But if you want to spend endless hours attempting to unsolder each capacitor connection and then during the process you break a lug on a tube socket or coil form you will not be happy so just do the pigtails and get on with the project.

More info on replacing

capacitors can be found at N3FRQ's web page.

http://www.skywaves.ar88.net/commrx/Maintenance/Comprepl/component_replacement.htm

Scrape

and clean leads before forming the pig tails.

When soldering the leads use a very small amount of flux to ensure a good connection.

During the recap process stay organized. Make up a column chart with the Part # - Value - Circuit Function- resistance check - tested value of removed cap etc. Measuring and testing the cap after removal makes you feel good when you discover leaky or out of tolerance caps.

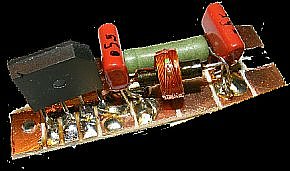

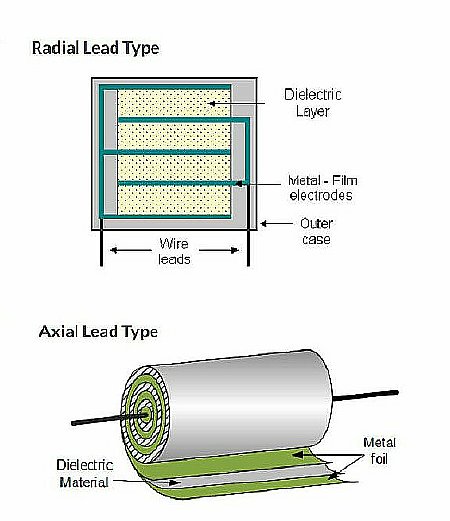

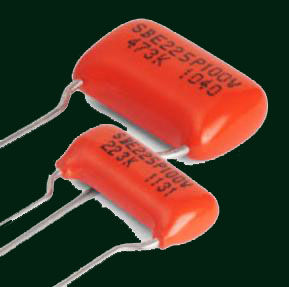

The

newer caps are available in a smaller package. Construction

of these caps is usually Metal-Foil Polypropylene or Metalized

Polypropylene Film what ever that means. You can easily obtain a capacitor

half the size of the original Postage Stamp yet have a voltage rating

of 630 volts.

Photo

by electronics-tutorials.we/capacitor/cap

There is plenty of room in the receiver to allow installation of either radial or axial lead capacitors.

Both

radial leads and axial lead caps were used as they were available in my

capacitor box.

Here

are several links to suppliers:

https://www.tubesandmore.com/products/capacitors

The latest fad is to use all "Orange Drop" capacitors. They are a pretty color but expensive. Available in radial lead configuration only. They are available but you may have a hard time finding a source for all of the values needed in the receiver and transmitter. Just mix and match the capacitors and get on with the project.

HINT:

Confirm the value of the new cap before installation. Use the proper

voltage rating. A 100 volt rating could be used for replacement caps in

the receiver but I prefer to use 200 volts or higher. The transmitter

requires higher voltage ratings in the later stages. There are plenty

of "digital" capacitor testers available on ePay. Be

careful when measuring large value electrolytics with a digital tester

- be sure and complete discharge the capacitor first!

Be sure

and replace C43 and C45 100 uF electrolytic. They are not Good and certainly

they are Bad and definitely Ugly. They are used as noise suppressers on

the filament line. Don't screw around just change them.

The new C43 and C45 100 uF replacements.

Plenty of room on the individual chassis boards and actual chassis for the new smaller size caps. The new electrolytics are also a lot smaller. Be sure and secure the large electrolytics with lacing. Don't forget to insulate the leads on all caps when necessary. I prefer Teflon spaghetti insulation available on ePay as it does not melt when soldering.

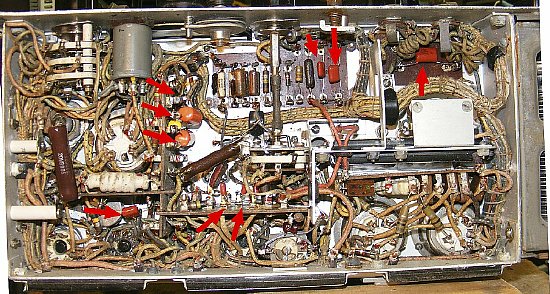

CLICK to enlarge

Receiver Chassis bottom view - arrows point to new capacitors. Most of the replacement capacitors had radial leads as they were available in my capacitor box.

Transmitter

chassis with new caps. I may have missed arrows one or two. Don't screw

around and waste time just go ahead and replace all of the paper capacitors.

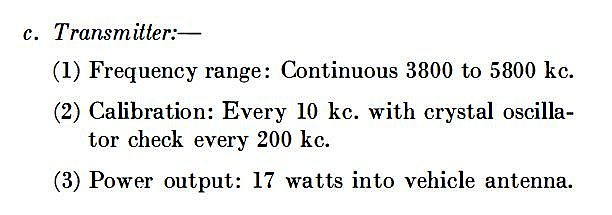

PROBLEM: The BC-654 receiver or transmitter frequency coverage does not include the lower end of 80 meters. The entire Extra Class Phone and CW segment are also not covered.

The BC-654 receiver or transmitter frequency coverage does not extend below 3800 Kcs. You are SOL if you want to operate 80 meter CW or use portions of the Extra Class segments.

Q: Will the dial markings

be accurate on the transmitter and receiver dial after the frequency modifications?

A:

No - you can make up a correction chart and/or use a label marker for

new dial markings.

Q: will the calibration

oscillator still operate every 200 kcs.

A: Yes

Q: Can the mods be easily reversed?

A: Yes - the modification caps can be tack soldered in place.

Q: Its is legal to operate CW in the phone portion of 75 meters.

A: Yes

Q: Will receiver sensitivity be effected?

A: No

On

my receiver I extended the coverage down below 3.500 to cover NY VOLMET

on 3.485 Kc. It is a great site to demo reception of the USBSC on a WWII

receiver while attending a Military Rally. Google VOLMET.

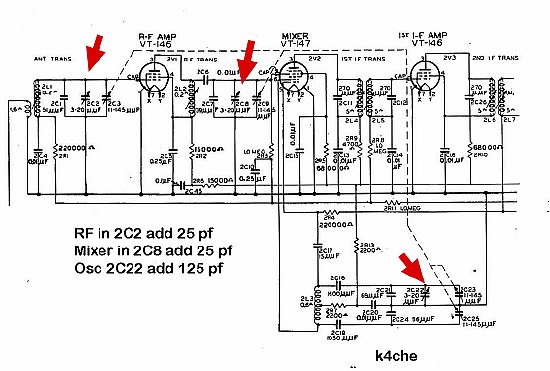

The receiver utilizes ceramic trimmers that are augmented with a fixed capacitor. Modifying the receiver for a lower frequency coverage can be accomplished by adding additional capacitance to the adjustable trimmer circuits to increase the "fixed" capacitance. The original trimmers will still function properly and can be used for alignment. There is a free lunch after all.

A typical ceramic trimmer capacitor.

When experimenting with capacitors in RF circuits a handy device is an adjustable trimmer with wire leads. Temporarily install in the circuit and adjust the trimmer for best performance - then remove and measure the capacitance of the trimmer. Replace with a fixed capacitor.

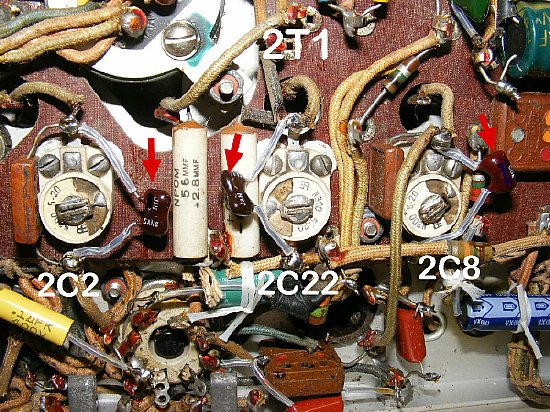

Lower frequency modification caps have been installed on trimmers 2C2 ( RF In) , 2C22 (Oscillator) , and 2C8 (Mixer In) . Trimmers can still be adjusted for alignment. I chose 3.5 and 4.6 Mc for alignment points.

Note: The modification values for the RF and Mixer sections were found by setting the antenna (2L1) and RF coil (2L2) about 5 turns from the bottom then setting the trimmers to approximately 1/2 capacitance and then experimenting with adding additional "fixed" capacitance to the receiver trimmers. After installing the additional "fixed" capacitors you can easily "touch up" the circuits on 75/80 meters by just using the antenna (2L1) and RF coil (2L3) adjustments accessible from the top of the receiver if necessary. Play with it - its not that complicated. The set tracks well across the 75/80 meter band and still functions well above 4.0 Mcs.

Labels can be added for the new frequency coverage. They can be removed.

Problem: The BC-654 receiver usually lacks sufficient BFO injection to provide adequate CW reception. The injection level is easily improved with a reversible modification. The mod also lends itself to demonstrating the receiver on 75 Meter SSBSC or DSBSC.

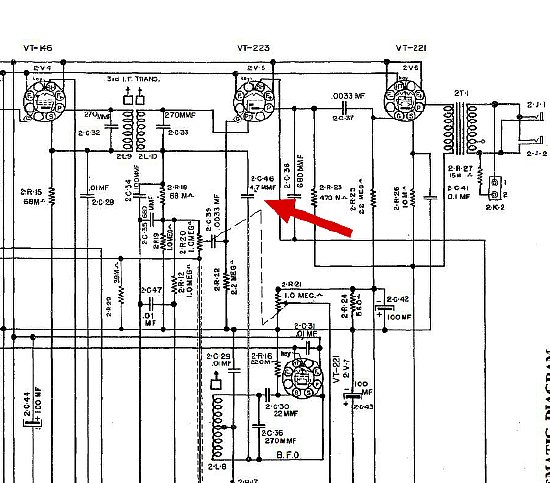

CLICK to enlarge

Capacitor 2C46 a 4.7 pf is used to couple the BFO injection to the 3rd IF transformer. The value of 2C46 is usually too small in value for sufficient coupling and needs to be augmented with a larger value. Experiment with a 10 to 20 pF placed in parallel with 2C46.

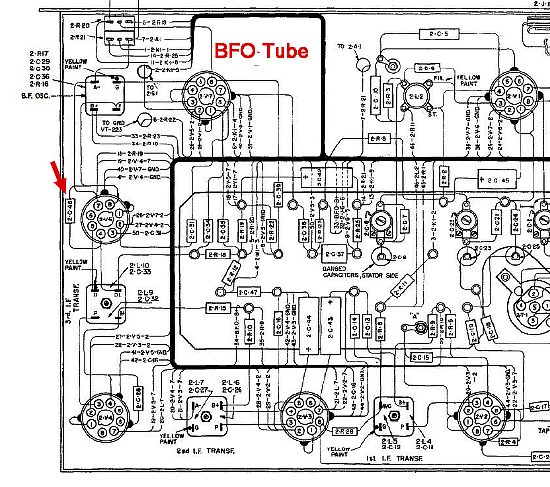

CLICK to enlarge

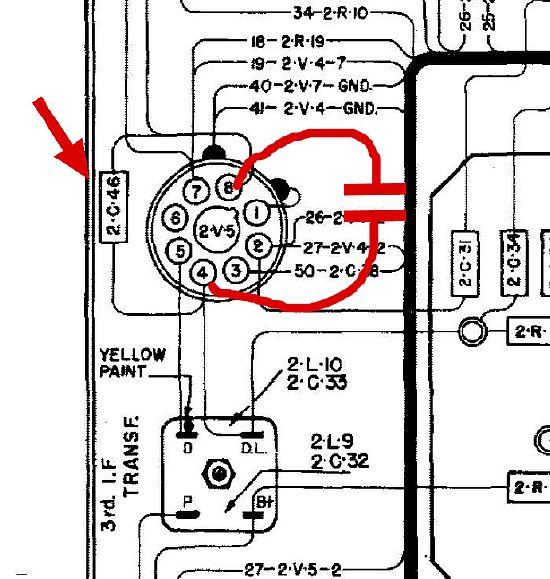

2C46 is not mounted in the BFO tube area as it is mounted on spare lugs 4 and 8 of socket 2V5. This places it at a convenient point between the BFO tube 2V7 and the 3rd IF 2L9/10 IF can.

Solder

your additional capacitor across 2C46.